Concrete Precast Manufacturer

Ericsson Mfg. Ltd. is always striving to find

ways to improve your work environment.

About

Ericsson Mfg. Ltd. is the leading manufacturer of

concrete bases for sign posts, located in lowermainland BC, Canada

Ericsson Mfg. Ltd., the proven product on the Recognized Product List for the BC Ministry of Transportation and Highways, Report 350, Federal Highways, CALTRAN and WSDOT approvals included.

Bases

Model B

Proposed for a 2 -3/8" O.D. circular post.

1/2" by 3/4" stainless steel set screw included.

Model C

Proposed for a 2" square tube post.

5 mm (3/16") thick wall, drill hole for 3/8" bolt or rivet.

Model C-S

Proposed for a 2 1/4" square tube post.

Single break-away sleeve only, drill hole for 3/8" bolt or rivet.

Model D

Proposed for a 1 -3/4" square tube post.

Double sleeved telespar wall, drill hole for 3/8" bolt or rivet.

Products

Concrete Bases

Concrete bases come with a standard break -away sleeve of 6" thereafter a well through the concrete base. These standard bases are available in 24 kg and 37 kg. Bases are also available with a full length sleeve --recommended when installation of the sign post does not go the length of the concrete base. Full length sleeves are available for 37 kg. All 46 kg, 85 kg and 175 kg are only available with full length sleeve.

Freestanding Bases

Proposed for a 2 3/8" O.D. circular. 1/2" by 3/4" stainless steel set screw included. Proposed for a 1 3/4" square tube post. Double sleeved telespar wall, drill hole for 3/8" bolt or rivet. The bases are available in 40 kg and 96 kg. Both sizes are 19" square at the bottom. The 40 kg has a height of 6". The 96 kg a height of 9".

Valve Box Pads

Concrete ring reinforced with 2 rebar rings, approx. weight 25 kg (55 lbs). Size being approx. 18 -1/4" O.D., 3" thick. The inner hole is diameter approx. 8 -1/8".

Sidewalk Sleeves

Sidewalk sleeve proposed for 2 3/8" O.D. circular pipe post 1/2" by 3/4" stainless steel set screw included. Available in 12" or 18" lengths. Square tube variety available as well.

More Products

Pavers-base

Concrete base with extended sleeve was designed for the use with paver stones. The extended sleeve allows for space for the installation of pavers without hindering the use of the break-away sleeve. The sleeve extends approx. 5 1/2" above the concrete. Available for use with the pipe sign post, weight 37 kg and 24 kg.

Base Specs

Weight Length Top Sq. Bottom Sq. Common Applic.

24 kg (53 lbs) L=12" 6" sq. 8"sq. asphalted islands **

37 kg (81 lbs) L=18" 6" sq. 9"sq. standard city base

46 kg (101 lbs) L=20" 6" sq. 10"sq. hwy/urban cities base

85 kg (185 lbs) L=23" 8" sq. 12" sq. hwy/urban cities base

175kg (385 lbs) L=24" 11"sq. 17" sq. wind/snow loads

** for use in applications with low lying obstructures limiting the depth for burial - note this base intended for use with concrete patch -to secure the base.

Installation

2. Insert the post or lifting tool into the sleeve and slide it downwards to the bottom of the base. Secure with set screw provided or 3/8" bolt for square tube post.

Install. cont.

4. To level the post and concrete base, scoop some dirt on the one side of the base while leaning the post in the opposite direction until dirt falls under the base. Repeat this procedure for the other side if necessary. .

5. Once the post is level, refill and pack remaining dirt.In a couple of weeks, rain will compact the ground surrounding thebase making it very stable.

Accessories

The diagrams depicted are recommended for use in installation of the concrete bases. Ericsson Mfg. Ltd. does not produce the lifting tools but scrap sign post can often be used to create a version of the diagram.

The lifting tool center piece (3 ft in length) made from standard sign post material.

The handle (1 ft length) can be made from angle iron, flat bar, or a square tube piece. For use with the freestanding base, it is recommended the top cross bar material be 3 ft to accommodate the 19" width of the freestanding base. This will allow one person to walk easily on each side of the freestanding base.

Tighten set screw or 3/8" bolt to secure tool to the concrete base when lowering into pre-dug hole.

Contact

Should you wish to contact us via email, please send inquires to:

office@ericssonmfg.com

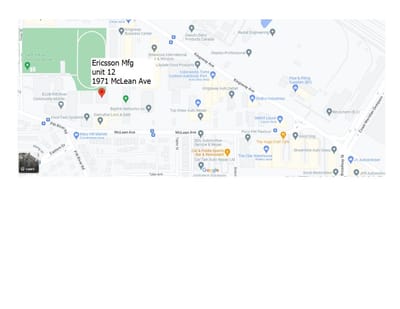

Ericsson Mfg. Ltd. is located in the heart of Port Coquitlam, BC.

Our mailing address is:

34785 Armstrong AveAbbotsford, BC

Canada V2S 7Y8

Office: 778-908-4777

Shop: 778-345-7129